FIRE EXTINGUISHING SYSTEMS

Wet System

It is the first preferred system type in fire systems. In wet systems, pressurized water waits inside of pipe and immediately begins to be discharged with the operation of the relevant extinguishing equipment. The reason why this system is preferred in fire cabinet, hydrant and sprinkler systems is that it provides the opportunity to directly intervene in the fire without delay. The main control valve used in this system is called wet alarm valve system.

Dry System

It is the second most prefered used system after wet system. They are used for an alternative to wet systems where there is a risk of freezing (where the ambient temperature may fall below + 4°C) Different from wet systems, it waits in the compressed air or nitrogen inside of pipe instead of pressurized water and with the operation of the relevant extinguishing equipment. Firstly air or nitrogen is discharged and later water is observed to discharging. The main control valve used in this system is called dry alarm valve system.

Pre-Action System

They are the preferred systems in areas where valuable items (artworks, manuscripts, important document archives, etc.) are protected from water damage caused by incorrect activation. As in dry systems, pre-action systems also contain air or nitrogen inside of the pipe.

With the operation of the relevant extinguishing equipment, first the air or nitrogen in the line is discharged but the water isn't allowed to discharging immediately. Meanwhile, a pre-fact is given by warning alarm devices on the main control valve. Confirmation is expected from other detection devices and allow the water discharging. In the event of a real fire, the extinguishing equipment will be disharged after detection devices will confirm the fire. In this way, the water will reach the discharge devices and extinguishing process will start. The main control valve used in this system is called pre-action alarm valve system.

Deluge System

These are systems in which water is discharged simultaneously from all extinguishing equipment connected to the same system using open-ended extinguishing equipment (nozzle, sprinkler without glass bulb, foam makers, etc.). In these systems, pipes and extinguishing equipments are connected to the main control valve (deluge valve). All pipes above the main control valve are empty and the main control valve is opened with the command from the detection system, and the fire is intervened with all extinguishing equipment at the same time. Generally in the design of special extinguishing systems preferable. The main control valve used in this system is called deluge alarm valve system.

Sprinkler Systems

Sprinkler systems are designed and installed to protect against loss of life and property in the event of a fire and consist of equipment such as sprinkler heads (sprinklers), valve groups, distribution pipes, pump group providing pressurized water.

Heat sensing element when one or more sprinkler heads are exposed to sufficient heat in the event of a fire (fusible link or glass bulb) becomes active and the pressurized water is distributed within a specific spray characteristic.

The activation temperature of the sprinkler thermal activation element is selected according to the ambient temperatures in which the sprinkler is used and they become active when this temperature is reached.

Protection areas can be 21m2, 12.1m2 and 9.3m2 depending on the hazard classes of the areas where they will be used. There are also special types of sprinklers with large protection areas.

Sprinkler systems are used in many areas such as car parks, shopping malls, high-rise buildings, workshops and storage areas.

System designs are made based on standards such as NFPA13, FMDS02-09, EN 12845 etc.

Fire Cabinet Systems

It means a fixed installed system to enable people to control and extinguish a small fire nearby. Fire cabinet system consists of fixed units mounted on walls or inside cabinets and permanently connected to a water supply system.Fire cabinets can be different according to their usage areas and material contents. These differences are determined according to the intended use and the appropriate cabinet type is selected.

According to Turkey Fire Protection Regulation 2015;

Workshops, warehouses, accommodation, health, gathering and education buildings with a total indoor area of more than 1000 m2,

in parking garages whose total area is larger than 600 m2,

In boiler rooms with a thermal capacity of more than 350 kW,

fire cabinet system is required.

Fire Hydrant Systems

Fire hydrant systems provide a pressurised water resource to firefighters' hoses at inside and outside the building.

Generally, when it comes to hydrant system, the first thing that comes to mind is the outer field type fire hydrant systems surrounding the facility, but there are also systems used in the building, also called "Fire Hose Valve Systems".

According to Turkey Fire Protection Regulation 2015;

It is mandatory to make fire hose valve system in buildings with any dimension more than 60m or a floor area of more than 1000m2.

It is compulsory to make outside type hydrant systems in facilities whose total base areas exceed 5000m2.

Hydrant system design flow must be at least 1900 l / min @ 7bar.

The distance between hydrants are 50m in high-risk areas, 100m in risky areas, 125m in medium-risk areas and 150m in low-risk areas.

Under normal conditions, hydrants are placed at an average distance of 5 to 15 meters from outside surface of buildings.

If the piping system providing water to the hydrant system is not designed as a ring system, the diameter of the smallest pipe that can be used should be 100mm and it should be determined according to the hydraulic calculation.

Water Mist Systems

Compared to the conventional sprinkler system, by separating the water into smaller droplets (500-1000µm on average), expanding the heat transfer surface of the droplets during extinguishing and evaporating these droplets in a shorter time (thanks to change of state, very serious energy absorption from the environment) the energy of the fire is reduced and a great cooling effect is provided.

In addition, water passing from the liquid phase to the gas phase (steam) during the process prevents the oxygen in the environment from directly reaching the flammable surface intensely and creates a suffocating effect.

At the same time, it can enter into closed systems and in this way it performs 3-D quenching.

Although it is categorized differently in European and American standards, the most common form is water mist systems according to operating pressures;

a) Low pressure,

b) Medium pressure,

c) High pressure water mist systems.

System designs are made based on standards such as NFPA750, FM5560, EN 14972, VDS CEA 4001 etc.

Foam suppression systems are preferred on the purpose of they provide effective extinguishing in flammable and combustible liquids that can't extinguish by water.Correctly designed foam extinguishing systems in areas where flammable and combustible liquids are used in production or stored can extinguish the fire in a short time.

Combustible liquids are chemical liquids with a flash point of 38°C and above, and flammable liquids with a flash point below 38°C.

Flammable and combustible liquids consist of petroleum-derived hydrocarbons and polar solvents.

Hydrocarbons are organic compounds containing only carbon and hydrogen atoms. (Gasoline, diesel, fuel oil, oil etc.)

Polar solvents are liquids that can be mixed with water and used as solvents. (Alcohol derivatives, acetone, ammonia, ethyl acetate etc.)

Foam suppression systems, provide some advantages by making a film layer on the surface of the flammable substance;

Foam film layer cuts the contact between fuel vapor and oxygen.

Foam film layer prevents evaporation on the fuel surface,

Foam film layer separates the fuel surface and flame from each other.

NFPA11, NFPA16, NFPA30, NFPA409, NFPA418 standards are the most used standards in the design of foam suppression systems.

Foam Types According to Substances

Protein Based : Protein (P) , Floroprotein (FP) , Film Forming Flouroprotein (FFFP) , Alcohol Resistant Film Forming, Fluoroprotein (AR-FFFP) i

Synthetic Based : Synthetic Aqueous Film-Forming Foam (AFFF , Alcohol Resistant Aqueous Film Forming (AR-AFFF)

Foam Suppression System Types Classified by Expansion Rate

Medium Expansion Foams: <1:20

Medium Expansion Foams: 1:20 / 1:200

High Expansion Foams: >1:200

Where can be used ?

Flammable & Combustible Luquid Storage ; Printing & Painting Manufacturing ; Tank Farm; Petrochemical Industry and Rafinery ; Power Plant ; Chemical Manufacturing Factory ; Maintenance Shop ; Shipyard and Port ; Aircraft & Helicopter Hangar ; Airport

Gas suppression systems basically perform extinguishing functions with 2 principles;

1- By absorbing the heat of the room, making the burning materials fall below the ignition temperature

2- Ensuring that the oxygen level in the environment falls below the minimum 14% required for combustion."

These types of systems are used in special areas that need to be protected from water damage.

Clean agent suppression systems ensure that our systems continue to work quickly without damaging the environment after the fire extinguishing process.Clean agent suppression systems can be used under certain conditions, even in rooms where people are present.

Non-clean gas systems can only be used with special conditions for some areas where there is no live inside.Since these systems have no electrical conductivity, they are safe for humans and the environment."Gaseous suppression systems have very common usage areas as they do not leave any pollution after extinguishing and offer flexible usage options. This is why they are especially preferred in critical areas of vital importance.

USED IN ; CCTV Rooms,Battery and UPS Rooms,Electric Rooms,Transformet and Generator Rooms,Flammable Liquied,Storage Areas,Data Centers,Archives,Libraries,Banks,Museums

The most preferred design standards for these systems in the world are NFPA2001, EN15004 / ISO14520.Designs should be made according to the same standard to cover the entire system and equipment, and product types should be selected accordingly.It is very important that the systems have been tested and approved by internationally accredited organizations such as UL, FM, LPCB, VdS.

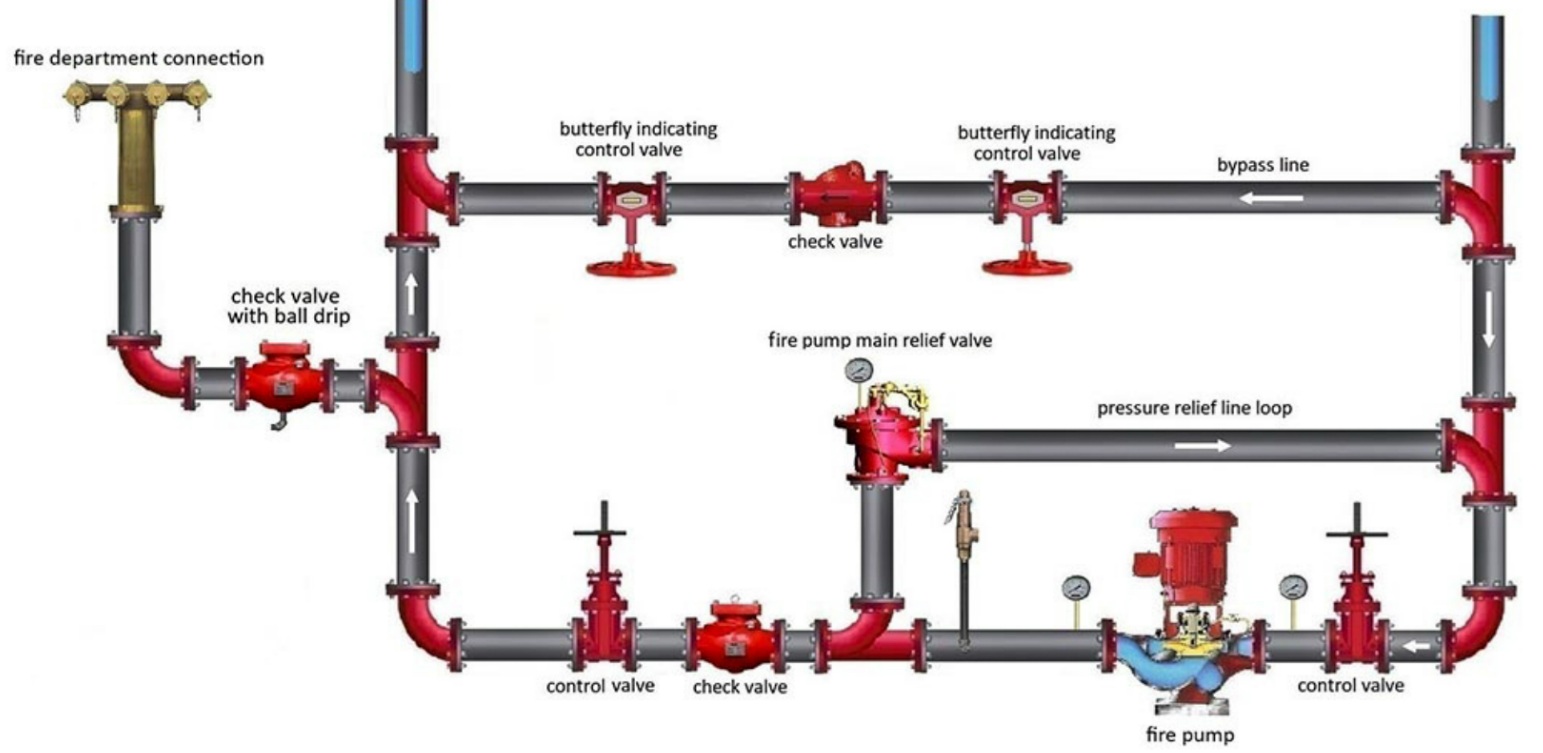

Fire pump systems are used to meet the critical water flow and pressure calculated as a result of the design of extinguishing systems.

They continuously supply water at the required flow rate and pressure to all systems that need pressurized water such as sprinklers, fire cabinets, indoor and outdoor hydrant systems.

What Are The Basic Features of Fire Pumps Different From Other Booster Groups?

Unlike water boosters, fire pumps have operating curves parallel to the horizontal. (Flow-pressure optimization)

Fire pump systems consist of main pumps and jockey pumps.

Main pumps are necessarily supplied with redundancy.

By taking precautions against energy cuts of fire pumps, it is ensured that they work even in the worst scenario.

Periodic testing and maintenance of fire pumps is mandatory.

What Are Pump Selection Criterias According to NFPA20?

The three main factors to be considered about fire pumps;

The pressure value obtained when the pump reaches 150% of the nominal flow rate value should not be less than 65% of the nominal pressure value.

The pressure value obtained against the closed valve (at 0% flow) should not be more than 140% of the nominal pressure.

It should be approved that it will provide the declared flow rate and pressure values according to the reference values (kW / hP) and that it is produced in accordance with intended use.

What Are The Fire Pump Types?

According to Suction Type and Physical Properties

End Suction Fire Pumps

Horizontal Split Case Fire Pumps

Vertical Turbine Type Fire Pumps

By Drive Type

Electric Motor Fire Pumps

Diesel Engine Fire Pumps

The most preferred design standards for these systems in the world are NFPA20 and EN12845.

Designs should be made according to the same standard to cover the entire system and equipment, and product types should be selected accordingly.

It is very important that the systems have been tested and approved by internationally accredited organizations such as UL, FM, VdS.

Fire pump systems have many auxiliary environmental equipment such as relief valves, waste cone, flow meters, pressure gauges, vacuum gauges, test valves, etc. The types and characteristics of these peripheral equipment are determined according to the flow rate and pressure values of the main pumps (main – reserve).